Precision CNC Machining

for Critical Components

Custom CNC Services from a Trusted

Manufacturer

Trusted by decision makers at

As a full-service CNC machine shop, Macfab offers precision machining, cleanroom services, testing and assembly, inventory management for tighter cost control, raw materials tracing, and specialty finishing for our customers, partnering together in the increasingly competitive global environment.

When manufacturing critical CNC components, there is no room for delays or substandard quality—Macfab ensures reliable delivery and unmatched precision to keep your production on schedule. Setbacks hinder your growth, push back production timelines, and clash with corporate mandates. The resulting cost escalations and missed project milestones can erode your brand equity over time. The Macfab team has built its reputation over many years in delivering the highest quality CNC machining services to meet your critical timelines and high precision specs.

Our Services

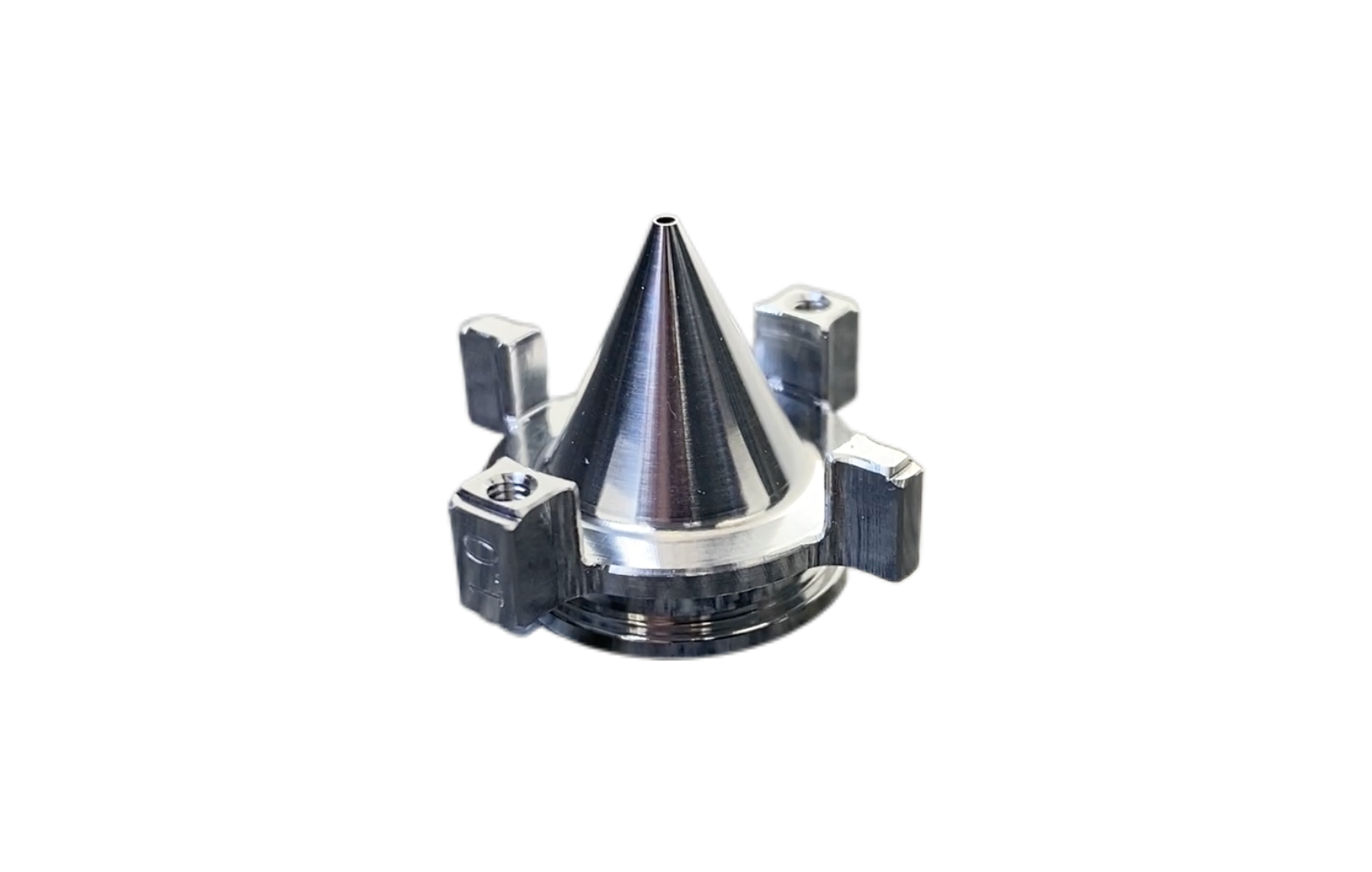

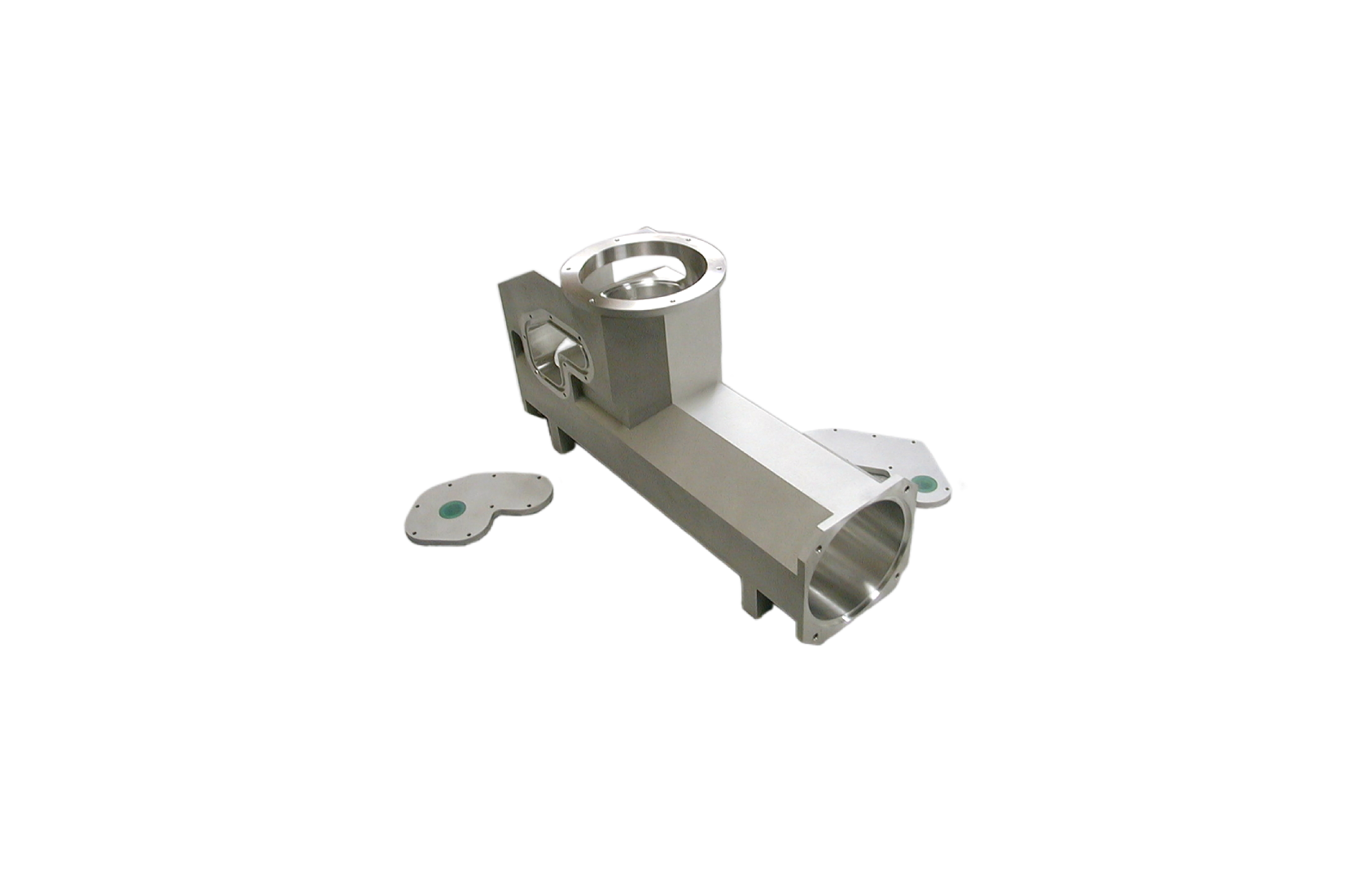

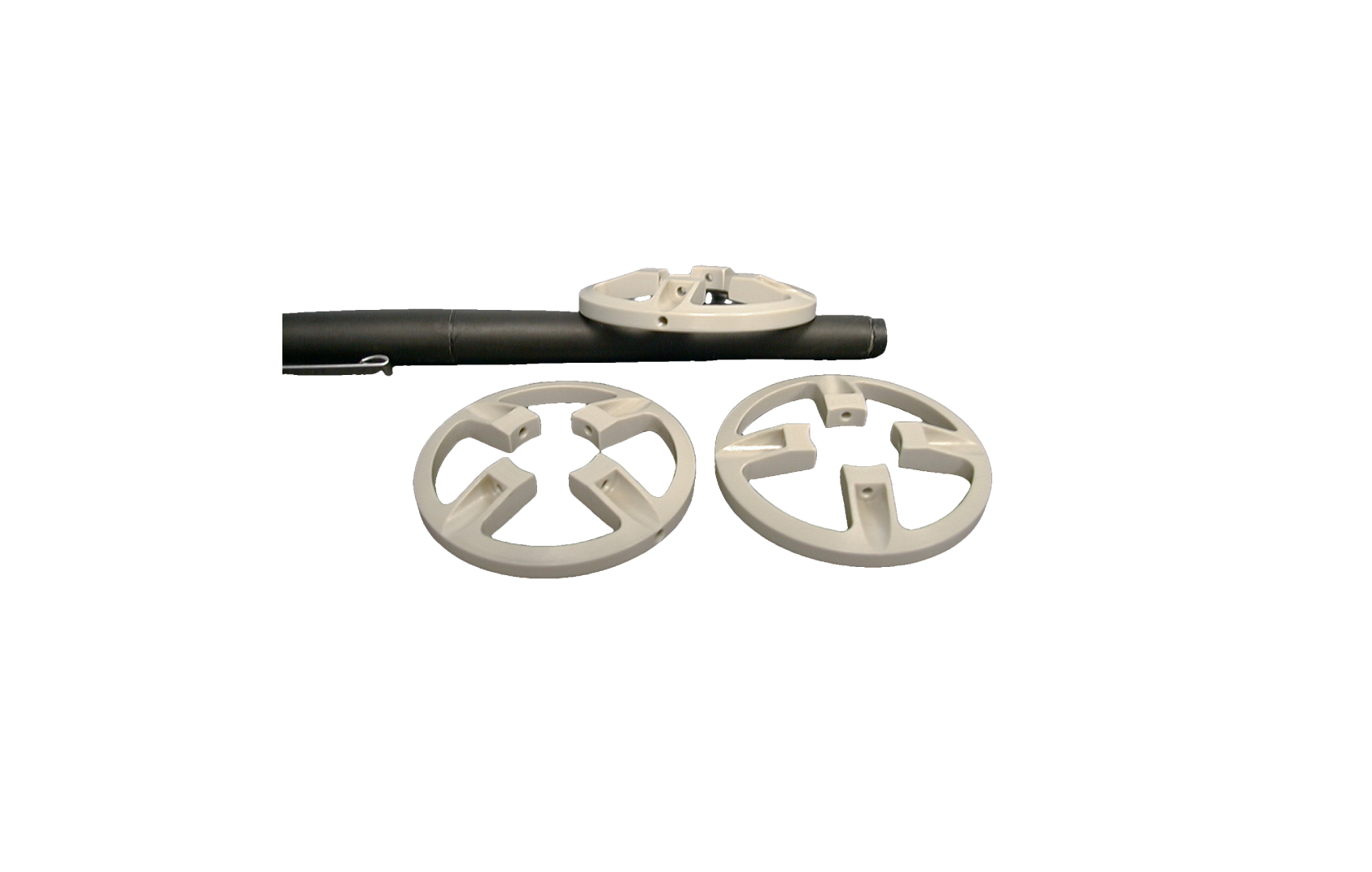

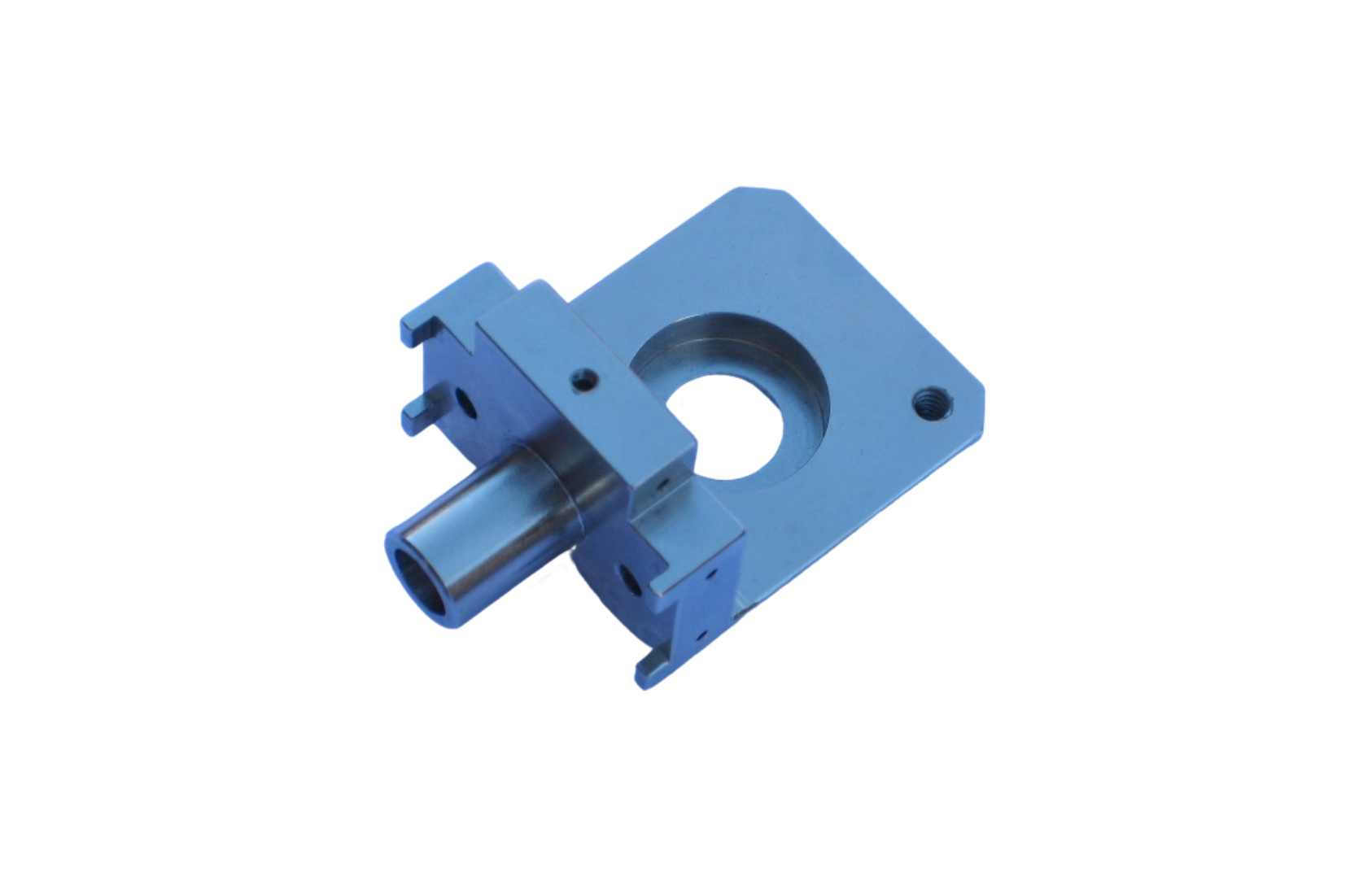

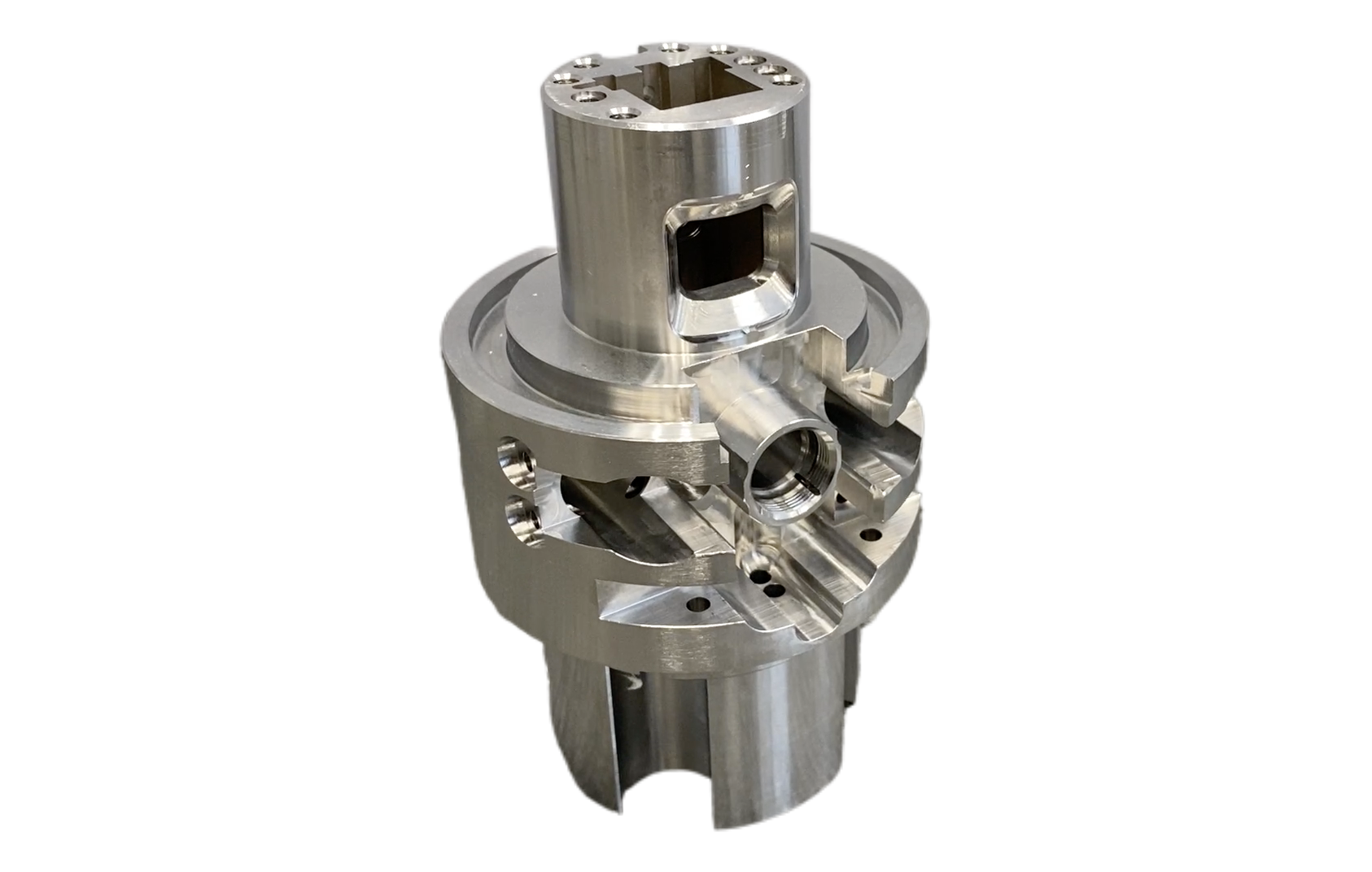

Multiaxis turning, precision milling, CNC prototyping, assembly services, and specialty cleaning are among Macfab’s areas of expertise. Our cutting-edge capabilities enable the manufacturing of components with tight tolerances for demanding industries. We offer outstanding quality, accuracy, and consistency at every stage of CNC machining and finishing, whether it’s for complex production parts or short-run prototypes.

We work with your teams from prototype development through each stage in the process to deliver top-quality machined and assembled parts to your facility, ensuring every component meets your specifications and performance requirements.

Industries we serve

Macfab Manufacturing is a trusted partner for tight-tolerance, mission-critical components across medical, aerospace, space, environmental, and power generation industries. Our expertise in custom CNC machining includes precision CNC milling, multiaxis turning, fabrication, and complex prototyping to support your applications where accuracy and reliability are non-negotiable.

From satellite subsystems and gyroscopes to analytical instruments for virus detection and trace element analysis, Macfab delivers consistent performance to innovative companies in challenging environments.

Medical

Security & Defence

Aerospace

Space

Power Generation

Environment

PRECISION MACHINING & MANUFACTURING EXCELLENCE

We are AS9100 + ISO9001 certified and backed by over 35 years of experience in manufacturing to the highest standards in precision CNC machining services. Our CNC machine shop handles highly complex and custom critical component manufacturing for product development, precision machining, finishing, assembling, cleaning, and more.

Our engineers collaborate early to optimize designs for manufacturability, ensuring every component meets strict quality standards and specialized finishing requirements. As a leading supplier of conventional and CNC machine shop services, we can fulfill your manufacturing deliverables to give you an edge over your competitors.

Featured Projects

Our CNC Machining Products

FAQs

Macfab tackles complex CNC machining challenges that impact precision, lead times, and production efficiency. Our focus is on the following issues:

- Tight tolerances and complex geometries

- High-mix, low-volume production

- Material-specific machining difficulties

- Design for manufacturability (DFM) support

- Quality and regulatory compliance

- Extended supply chain coordination

Macfab can machine a wide range of materials using advanced CNC equipment. Our team works with:

- Metals:

- Aluminum alloys (including aerospace grades)

- Stainless steels (300 and 400 series, PH grades)

- Carbon steels

- Titanium

- Copper and copper alloys (e.g., brass, bronze)

- Inconel and other high-temperature alloys

- Plastics and Composites:

- Delrin (acetal)

- PEEK

- PTFE (Teflon)

- Ultem

- Nylon

- Glass-filled and carbon-filled composites

Macfab Manufacturing adheres to a comprehensive set of industry standards to ensure the highest levels of quality, safety, and environmental responsibility across all operations:

- ISO 9001:2015

- RoHS (Restriction of Hazardous Substances)

- REACH (Registration, Evaluation, Authorization and Restriction of Chemicals)

- CPG (Canadian Policy Guidelines)

Our turnaround times depend on the current workload and specific job requirements. While many product developers aim for lead times of under 4 weeks, our standard delivery typically falls within 6 to 8 weeks, depending on the project’s complexity and scope. Meeting tight customer timelines remains a key challenge—and priority—for our team. We support a range of industries throughout Canada and North America, with many of our customers located in Ontario manufacturing hubs such as Mississauga.

Macfab does not conduct plating processes in-house. Instead, we leverage a trusted network of approved vendors to subcontract all plating work, ensuring it meets our quality standards and customer specifications.